(Part 1 of 13 in series, Scaf 101)

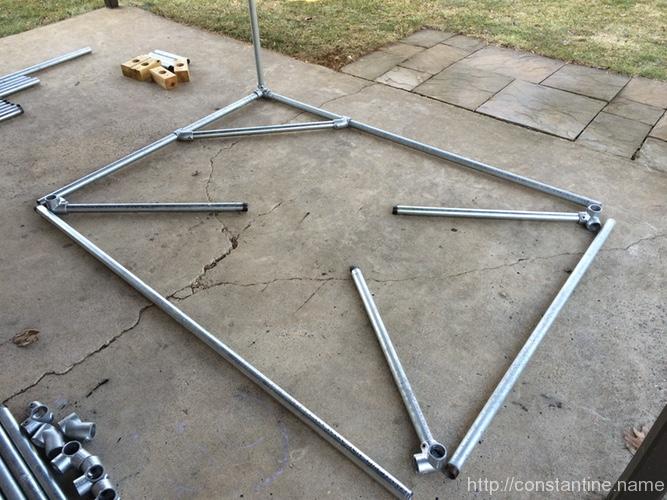

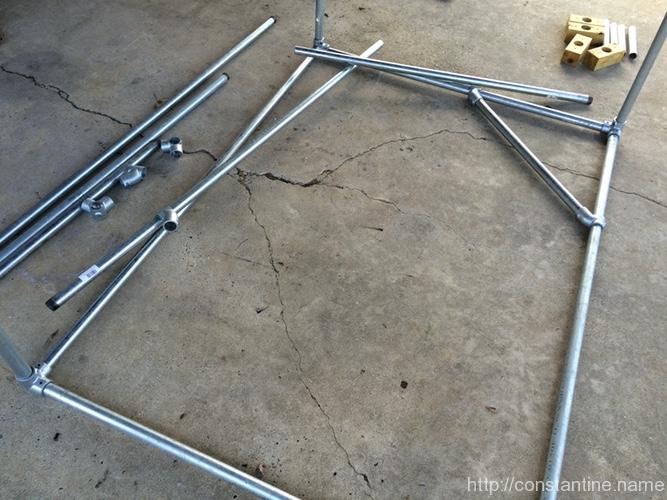

This series of posts (12 total, navigation is at the very bottom of each post) is intended to give you enough basic information to get started with scaf. I’m going to give you a specific list of things to buy — what I’m calling “The Set” — while trying to keep the cost as low as possible. I’m also going to show you a number of completely different things you can construct using the set.

In the initial posts, I’ll assume you know nothing and I’ll explain everything. As I show various setups, I’ll initially explain every step of assembly so you understand how to put things together without killing yourself (by working too hard, or by dropping pipe on your, or your friend’s, head). I do not recommend skipping to the end because the instructions on the later setups assume you understand what’s going on, and they only mention the “this is unusual or interesting” parts.

Once you spend some time building, and playing on, scaf, you’ll understand what is easy to build, what is hard to build, what is pretty stable and what is not. But how do you get started? The hard part is figuring out what should be the very first pile of stuff you buy. You want enough to have fun and options, but not more than you need, because scaf gets very expensive very quickly. VERY roughly, it’s almost $20 for every clamp, and almost $3 per foot of pipe.

This entire set is about $400 and will build you some really neat setups. There is a detailed parts list and buying instructions/links in the next post in this series.

Safety

Hey! Let’s get this out of the way now…

This sh*t is DANGEROUS. Seriously. You have been warned. I’m not being hyperbolic here.

The easy-to-get pipe used in this set comes with threads cut into the ends. The threads are razor-sharp. (The clamps cover the ends of the pipe.) I know what I’m doing, and still I’ve cut myself many times.

Steel pipe is heavy. If you lose control of even a seven-foot piece as you stand it on end, it will KILL someone if it falls on someone’s head. But what about pinched fingers and dropped-it-on toes? …I’ve had too many to count. Plus the old (not funny at all) slap-stick humor of carrying pipe, turning and striking someone with the end behind you. Steel pipe is heavy. There’s no “oops, sorry bro’,” just lacerations, crushed fingers, concussions and broken bones.

…and there’s the danger of the clamps working loose. You are planning to jump on, step on, swing from and generally use this NOT in the way the manufacturers intended. You have to learn how to align the pipe in the clamps, (or everything will wiggle loose even more quickly). You have to learn how tight to make the clamps, (so as not to break things, but tight enough to hold). You have to be smart enough to check and tighten things occassionally.

…and THEN there’s the danger of falling OFF the scaf. Or having it topple over ONTO you, or with you ON it. …or IN it.

Terminology

Back on day one of my Life With Scaf, this was very confusing and I wished someone had written a getting-started guide. So, here it is:

Kee Safety Klamps – This is a brand name of a type of pipe clamps. There is a whole collection of clamp types with neat names like “side outlet elbow”, “90 degree two socket tee”, etc. The set I describe in this series contains just three types of clamps that will get you started. As you buy more — and you will buy more because scaf is a highly addictive habit — you’ll have no problem figuring out what the other clamps are for.

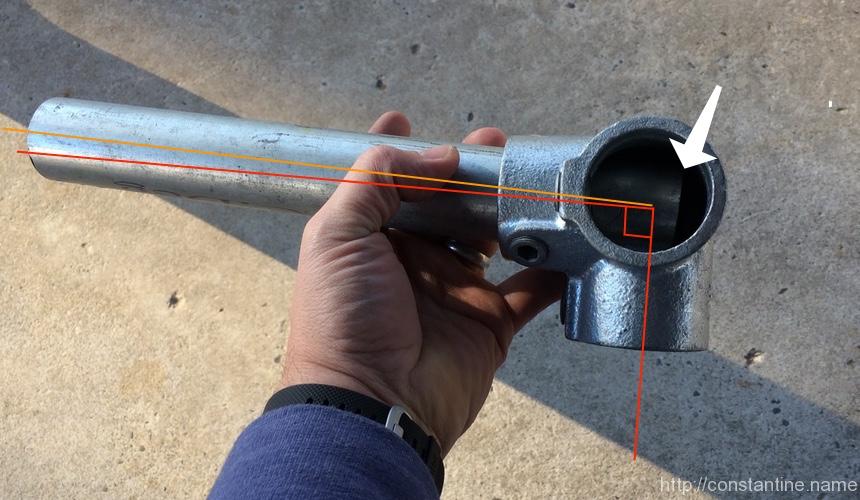

Set screw – Each clamp has several screws (one screw for each pipe the clamp accepts) that are threaded into recesses in the body of the clamp. You will need an 8mm Allen wrench to tighten them. Clamps come with their set screws but there’s no wrench. This isn’t IKEA. (More on wrenches later.)

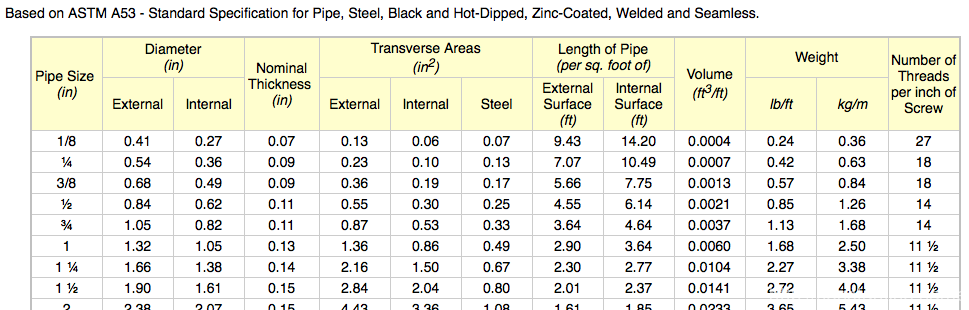

Schedule 40 – You don’t really need to know this, but it’s common to encounter the terms “schedule 40”, and “schedule 80”, when talking about scaf pipe. A “schedule” is a giant table of specific details like exact dimensions, and strengths for each of the various sizes of pipe. It’s used when building engineered structures where they’re computing loading for realsies with math. What we need to know for this series is that you want “schedule 40” pipe. (If anyone should ask you, that is.) Schedule 80 is much heavier, and therefore stronger, but is the same EXTERIOR size. So it fits all the same clamps as schedule 40 pipe. Down the road, you might want to shell out for a special schedule 80 pipe or two if you’re doing a lot of gonzo bar precisions or something. Anyway. You’ll have a good understanding of schedule 40 pipe after you play with this set. The longest pieces in this set are 7-feet, and they’re going to feel pretty nearly “bomb proof”.

1-1/4″ pipe – The least obvious thing about scaf is what size do you use? It turns out that this size is the best balance of weight, cost and strength. So the most commonly used size is “Size 7″. (For clarity: That is the seventh pipe size in schedule 40, also the seventh row in the table, and is known as 1-1/4″ or one and one-quarter inch.) Home Depot or other Big Box stores will just label it as 1-1/4”. Here’s the confusing part: There is NO dimension on 1-1/4″ pipe which is 1-1/4″. The interior diameter is close to 1-1/4″. Anyway. Just learn: “Size 7, otherwise known as 1-1/4″ pipe.” Kee Safety clamps have their size molded into their body; They have two numbers, like “20-7”, meaning clamp style 20, size 7. Again, after you play with this set, if you ever encounter a clamp that’s not size 7, it sticks out like a sore thumb. (I once received a pile of clamps in a box, and there was one number 8 incorrectly included… it was instantly obvious.)

Galvanized steel – You want “galvanized steel pipe.” You will also find “black pipe” at your local Big Box store. Do not use “black pipe”. For one thing, it feels different to the bare hands, and I like it less. For another thing, it will rust if you have it outside. “Galvanized” means the steel is coated with some Zinc. The Zinc will corrode away before the steel rusts, and black pipe is NOT galvanized. For yet another thing, I have NO IDEA about the strength of “black pipe”. When you cut pipe, you expose steel which is not galvanized, and lo and behold! …it rusts. The pipe in the photo never got wet, that’s just good old humidity and oxygen doing their thing. (“Rust never sleeps!”)

Summing up

We’re building this scaf set with size 7 Kee clamps, an 8mm Allen wrench, and schedule 40 galvanized steel pipe.

ɕ